Production of packaging film

Packaging film production is the process of creating thin film materials that are used to package various products for preservation, protection and presentation.

An important part of the production of packaging film is quality control at every stage to ensure that the final product meets the requirements of quality and safety standards.

Also, innovations in the field of materials science and processing technologies make it possible to constantly improve the properties of packaging materials, ensuring their compliance with modern product packaging needs.

In a general sense, the packaging film is an important component of the packaging of goods, which ensures their safety, protection and attractive appearance.

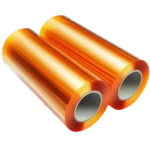

Packaging film

Packaging film is a thin layer of material that is used for packaging various goods in order to protect them from external factors such as moisture, dust, light, as well as for storage and transportation of goods. This material can be made from different types of plastics such as polyethylene, polypropylene, polyvinyl chloride (PVC), polyethylene terephthalate (PET) and others, as well as mineral materials such as aluminum.

Two-layer packaging film

Double-layer packaging film (duplex) is a type of packaging consisting of two layers of material, usually connected to each other by means of lamination or application of a special coating.

Three-layer packaging film

Three-layer packaging film (triplex) is an innovative material consisting of three layers, each of which performs its function to ensure reliable and efficient packaging of products.

Laminated packaging film

Laminated packaging film is a film created by combining several layers of materials using lamination and allows different materials with different properties to be combined.

Assortment of packaging film

There is a wide range of packaging films designed for different applications and storage conditions of products. These are just some of the types of packaging film that are used in industry and in everyday life for packaging various goods.

This is one of the most common types of packaging film. It can be transparent or colored, thin or thick, plain or laminated. Polyethylene film is used to package a variety of products, from food to industrial goods.

This film has high transparency and puncture resistance. It is often used for packaging food products such as snacks, confectionery and vegetables.

This film has high transparency and tear resistance. It is often used for packaging cosmetic and pharmaceutical products, as well as for creating labels and tags.

This film has high strength and resistance to thermal effects. It is often used for packaging products with a long shelf life, such as coffee, tea and dry products.

This film is highly stretchable and allows you to create tight packages that protect goods well from damage and contamination.

This film is highly resistant to punctures and allows you to create hermetic packages that keep products fresh for a long time.

Application of packaging film

Packaging film is widely used in various industries and households.

In the food industry, it is used to store and protect food products, ensuring their freshness and safety.

In the pharmaceutical field, it is used for packaging medicines and medical devices, ensuring their integrity and sterility. The cosmetics industry also uses packaging film to package cosmetics, ensuring their preservation and attractive appearance.

In industrial production, film is used for packaging and protection of various products during transportation and storage. Last but not least, in everyday life, packaging film is used to store and freeze food, as well as to cover containers and bags to ensure their freshness and cleanliness.

Thus, the packaging film plays an important role in the protection and storage of products in various fields of production and everyday life.

Purpose of using packaging film

The purpose of using packaging film is broad and multifaceted. The main purpose of using this material is to ensure reliable protection of goods during transportation, storage and sale. The film performs a number of important functions, including protection against moisture, dust, light and other external influences, which can negatively affect the quality of the product. In addition, it helps to preserve the freshness of products, ensuring their durability and preservation of useful properties.

Packaging also plays an important role in the presentation of the product, creating an attractive appearance and attracting the attention of consumers. In addition, it can be used to provide information about the product, such as composition, expiration date and other important data that helps consumers in making a purchase decision. In general, packaging film contributes to the quality and safety of goods, ensuring their effective presentation and preservation throughout their life cycle.

Advantages of packaging film

The film is an integral part of modern packaging and has many advantages. First, it provides effective protection of goods from various external factors, such as moisture, dust, light and mechanical damage, which can affect their quality and duration of storage. In addition, the film helps to extend the shelf life of products, preserving their freshness and taste. It also helps to save space during transportation and storage thanks to the compact packaging.

The transparency of some types of film allows consumers to view the product, while attractive designs and printed information can attract attention and attract buyers. Easy disposal and the possibility of processing some types of film contribute to reducing the negative impact on the environment. Finally, some types of film have high barrier properties that allow you to effectively protect goods from odors, gases or moisture. In general, the packaging film plays a key role in ensuring the protection, storage and presentation of goods, which makes it an integral part of any packaging.

Packaging film production technologies

The production of packaging film is a complex and technological process aimed at creating thin layers of material that are used for packaging various goods. In this process, the quality of raw materials, equipment settings and quality control of each stage of production play an important role. Production technologies are constantly being improved to improve the characteristics of the film and optimize the production process.

Preparation of raw materials

The initial stage is the selection and preparation of raw materials, which may include plastic resins, polymers, or other materials, depending on the requirements for the film.

Extrusion

The most common method of production of packaging film is extrusion. During this process, the raw material melts and flows through an extruder, where it is formed into thin film ribbons.

Cooling and hardening

After extrusion, the film is cooled to solidify and obtain the required strength.

Processing and application of additional layers

In some cases, additional layers or coatings may be applied to the film to improve its properties, such as UV protection or improved strength.

Cutting and winding

After the production is completed, the film is cut to the appropriate sizes and wound on rolls or blanks for further use.

Production of packaging film in Ukraine

Creation and purpose of the company for the production of packaging products

Smart Pack LLC is an important participant in the packaging film production market in Ukraine. We specialize in the production of various types of packaging films, such as polyethylene films, polypropylene films, stretch films and others.

Our company is known for its high-quality products, which are manufactured using modern equipment and advanced production technologies. We offer a wide range of films from different materials that meet the different requirements and needs of our customers.

In addition, we provide an individual approach to each client, providing services for the development and production of film taking into account the specific requirements and features of their products.

Thanks to our professionalism, high quality products and excellent customer service, "Our company" occupies a stable position on the market of packaging materials in Ukraine.