Production of wicket packages

Wicket bag manufacturing is a complex process of creating a specialized package using a wicket material that usually has a clear window or slot to display the contents of the bag. This process begins with the careful design and development of a packaging concept that takes into account functionality, aesthetics and marketing requirements. After that, suitable materials such as plastic, paper or others are selected that meet the quality and safety requirements.

The next stage is the production of the package itself, including such operations as forming, printing, cutting windows or holes, as well as other technological processes. After production, the packages undergo quality control to ensure compliance with all standards and requirements. Finally, the finished wicket packs are prepared for delivery to customers, which may include packing into boxes or pallets for shipping.

The production of wicket packs requires high quality standards from manufacturers, qualified personnel and modern equipment to ensure efficient and high-quality production. This process allows you to create unique and attractive packaging for various products that attract the attention of consumers and contribute to the success of the product in the market.

Wicket packages

Wicket bags (vacuum bags) are a special type of packaging materials used for packaging various goods, and usually consist of a film, which can be polyethylene or another type. Wicket bags have a special valve or mechanism for removing air.

The main advantage of wicket bags is their ability to remove air from the package, which allows you to store goods in a vacuum environment. This can significantly increase the shelf life of products, as the absence of air helps prevent oxidation and reduces the risk of bacterial growth.

Wicket bags are widely used for packaging food products such as meat, fish, cheese and other products. They are also useful for storing and protecting electronics, clothing and other products from moisture.

Use of wicket packages

Wicket bags have a wide range of applications, especially in the areas of packaging, storage and transportation of goods. In general, wicket bags are a versatile and effective means of storage and protection of various types of goods in many industries.

Individually designed wicket bags are the ideal solution for packaging various products such as bread, vegetables, poultry, hygiene products or clothing. They are made of different materials, which allows them to also be used for freezing goods.

Such wicket bags can be manufactured using different technologies from different materials such as polyethylene, polypropylene, plastic compositions, etc. depending on the need and requirements of the client.

Their versatility in use is particularly important: they can be loaded both manually and on automated high-speed lines, making them an ideal choice for various types of production and trade.

The design of wicket packs can be tailored to a specific brand or product, including logos, colors, product information and other elements, allowing you to create effective packaging to attract the attention of consumers.

Wicket packages for the food industry

Wicket bags are used for packing fresh products such as meat, fish, cheese, fruits and vegetables. They allow you to store these products in a vacuum environment, thereby reducing the risk of contamination and maintaining freshness for a long time.

Wicket packages for the cosmetic industry

Wicker bags are also used to package cosmetics such as creams, lotions, oils and other skin care products. They help maintain the quality and effectiveness of cosmetic products.

Wicket packages for the pharmaceutical industry

In the pharmaceutical field, wicket bags are used for packaging medicines, vitamins and other medical products that require long-term storage and protection from external influences.

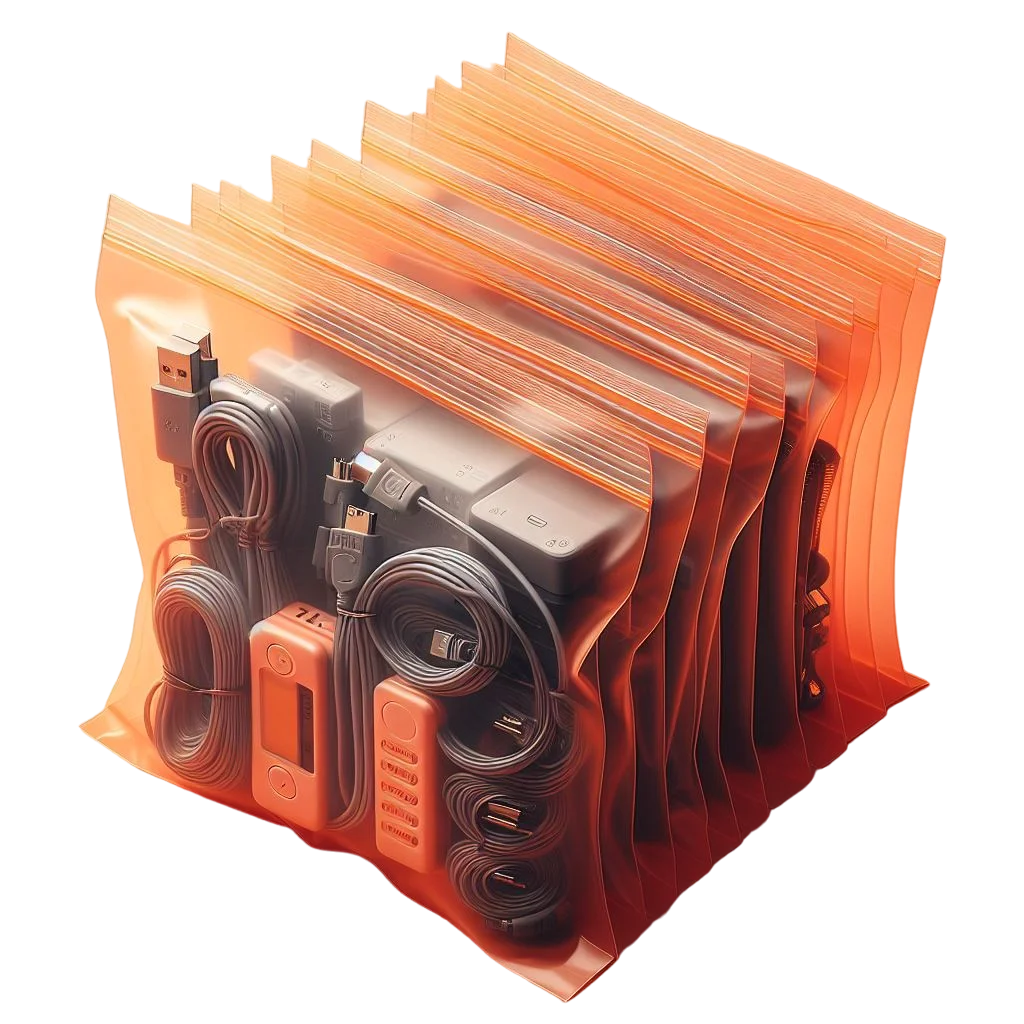

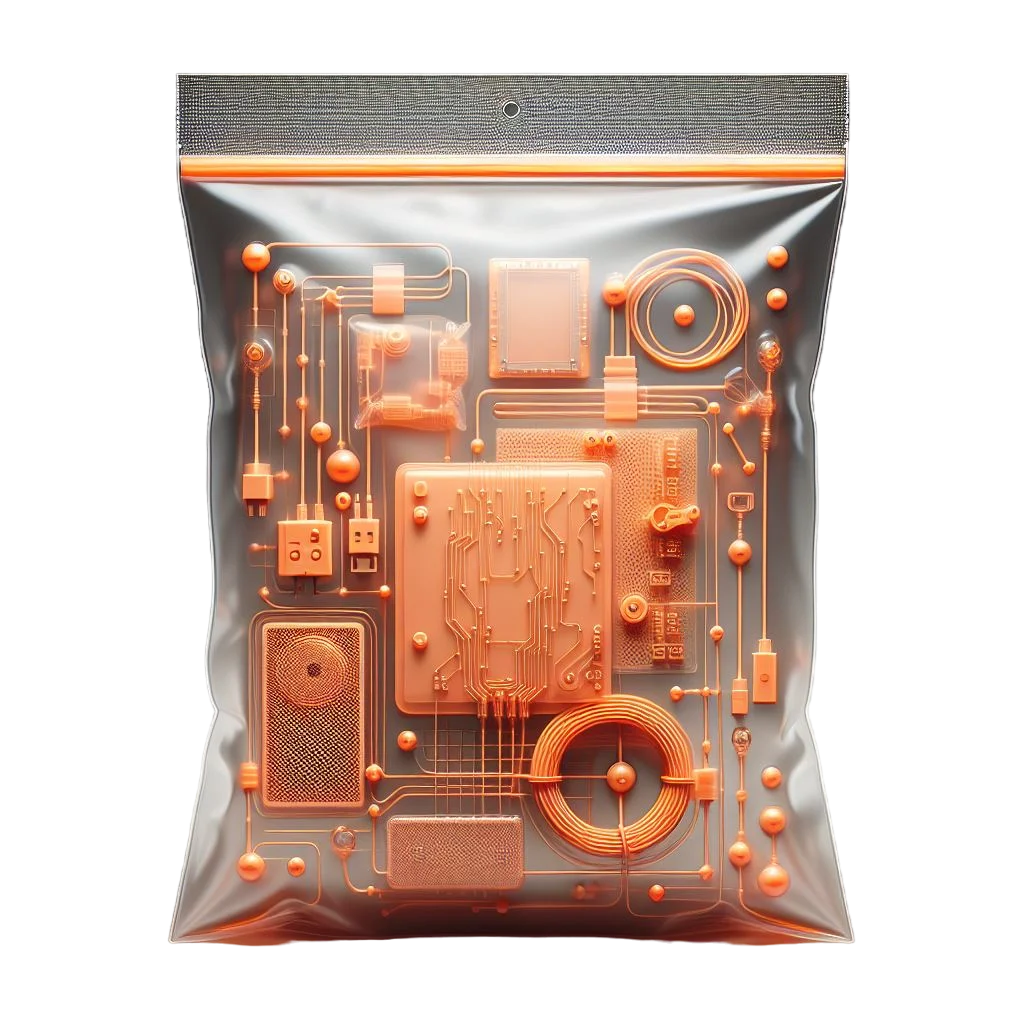

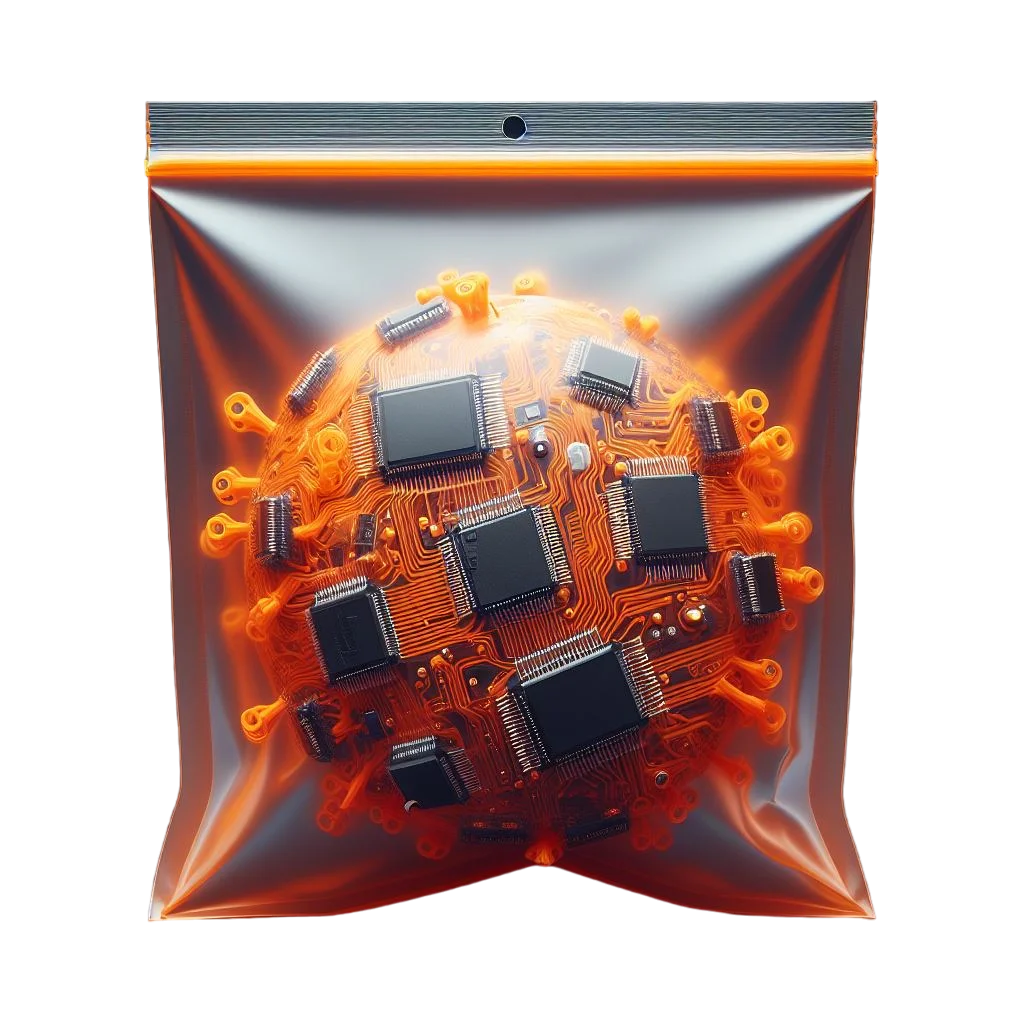

Wicket packages for electronics

In the field of electronics, wicket bags are used to package components, small devices and accessories. They help protect electronics from moisture, dust and other harmful factors during transportation and storage.

Wicket packages for household use

Wicket bags can also be used in the home for packing food for storage in the freezer or refrigerator, as well as for vacuum packing clothes and other items to protect them from dust and moisture.

Designer wicket packages

Designer wicket packs can be used in various industries such as food industry, fashion, cosmetics, gift industry and many others to create a positive consumer impression and increase brand awareness.

The purpose of using wicket packages

Wicket bags are an integral part of packaging for various goods, in particular in the food, cosmetic, pharmaceutical and other industries. The main purpose of their use is to provide effective protection of goods from external factors such as moisture, dust, light and mechanical damage. In addition, they are designed to preserve the freshness and quality of products for a long time, helping them to retain their nutritional properties.

Wicket packs also play an important role in the presentation of goods, creating a convenient and attractive appearance that helps attract the attention of consumers. Ease of use and information function are additional benefits of packages that contribute to meeting the needs of consumers and increase their satisfaction with the use of the product. Given their versatility and efficiency, wicket packages are becoming an integral component of packaging in many industries and households.

Wicket bags are an important component of packaging for the food industry, as they provide effective storage and protection of food products. In general, wicket bags play an important role in the food industry, ensuring the preservation of food quality and safety, as well as the convenience of their use for manufacturers, sellers and consumers.

Wicket bags for bakery products are an indispensable solution for packaging and storing bread, buns, rolls, pies and other products. They play an important role in preserving the freshness and attractive appearance of products, as well as protecting them from external factors such as moisture, air and pollution.

Wicket bags are used for packaging fresh products such as meat, fish, poultry, fruits and vegetables. Vacuum packaging allows you to preserve the freshness of products and extend their shelf life.

Wicket bags can also be used to freeze food. They create airtight packaging that helps avoid quality loss and protects products from freezing.

For restaurants, cafes and other public catering establishments, wicket bags are used to package prepared meals for delivery or storage.

Wicket bags can also be used for packing dry and packaged products such as cereals, coffee, tea, sugar, sweets, etc.

Packaging of products in wicket bags can also be carried out in the form of portions, which allows you to store products immediately in a ready-to-use form and facilitates their retail sale.

Wicket bags are also widely used in the cosmetic industry for packaging various cosmetic products. In general, wicket packs for the cosmetic industry help companies store and present their cosmetic products with maximum convenience for consumers.

Wicket packages can also be developed with individual design in mind to emphasize the brand and attract the attention of consumers. This allows cosmetic companies to produce attractive and effective packaging for their products.

Wicker bags provide a convenient way to package cosmetic products such as creams, lotions, skin care products, etc. They allow these products to be stored away from air and moisture, which helps maintain their effectiveness and long shelf life.

For cosmetic products based on oils and serums that require special attention to packaging to prevent leakage and contamination, wicket bags are ideal. They provide hermetic packaging, which helps to preserve the quality of the product.

Wicker bags are often used to package eye patches, face patches, and other cosmetic masks. They help retain moisture and active ingredients in the product, ensuring their effectiveness when used.

Wicket bags play an important role in the pharmaceutical industry, providing convenient and efficient packaging for drugs and medical products. In general, wicket bags play an important role in the pharmaceutical industry, providing safe, airtight and convenient packaging for various types of drugs and medical products.

Wicket bags are used for packing tablets, capsules and other forms of medicines. They provide protection against the effects of moisture, light and air, and also allow convenient dosing and administration of drugs.

Wicket bags can be used for packaging medical plasters, bandages and other medical materials. They provide airtight packaging that helps maintain the sterility and effectiveness of medical products.

Wicket bags are also used for packaging children's dosage forms, such as drops or syrups for the treatment of children. They allow convenient dosing and administration of drugs, and also store them in a safe environment.

Some wicket bags may be designed for packaging liquid dosage forms such as syrups, solutions and other liquids. They provide hermetic and safe storage of liquid preparations.

Wicket bags can be useful for packaging electronic components and devices, providing protection from external influences and providing convenience for transportation and storage. In general, wicket bags for electronics help to ensure the protection and safety of electronic components and devices during their transport and storage. It is important to choose the appropriate type of packaging depending on the characteristics and requirements of a specific electronic device.

For electronic components that are sensitive to static electricity, antistatic wicket packages are used. These bags have special anti-static properties to help avoid damage to electronics during transport and storage.

Some electronic devices can be packed in vacuum wicket bags to provide additional protection against moisture, dust and other external factors.

For electronic devices that require special protection from impacts and damage, special protective wicket packages are used. These bags can have a soft inner lining or a hard outer layer for added protection.

Wicket bags for household use are widely used for packing various household items and provide convenience and protection during their transportation and storage. Packing with wicket bags for household use is a simple but effective way of storing and organizing various household items. They are available in different sizes, shapes and colors, which allows you to use them for different purposes.

Wicket bags can be used for gift wrapping of various gifts. Thanks to the variety of colors and designs, they add an aesthetic look to the gift.

Wicket bags are often used to store food in the refrigerator or freezer. They help to avoid the penetration of odors and preserve the freshness of products.

Wicket packs can be used to organize things in closets, drawers or storage. They allow you to store things in an orderly manner and protect them from dust and dirt.

Wicker bags can also be used to store small items such as money, stationery or other small items. They help avoid losing or mixing things up.

Wicket bags are good for packing things while traveling or traveling. They provide convenient and compact packing of things and protect them from damage.

Designer wicket bags are a package that differs from ordinary bags with its special and attractive design. They are created on the basis of aesthetic and marketing aspects to attract the attention of consumers and emphasize the uniqueness of the product. Designer wicket packs can be used in various industries such as food industry, fashion, cosmetics, gift industry and many others to create a positive consumer impression and increase brand awareness.

Designer wicket packs have an attractive and stylish appearance. They can use bright colors, interesting graphic elements, unusual shapes and textures to attract the attention of consumers.

Designer wicket packs often feature branding elements such as logos, slogans or corporate colours. This helps emphasize the brand identity and makes the packaging recognizable among competitors.

Some designer wicket packs are made using exclusive materials such as special types of paper, textile or cardboard. This can give the packaging a luxurious or unique look.

Designer wicket bags may have special features such as additional pockets, carrying straps or other innovative features that make the pack more user-friendly.

Some designer wicket bags are made from environmentally friendly materials or may have advanced recycling. This corresponds to modern trends in sustainable development and allows companies to emphasize their environmental responsibility.

Advantages of wicket packages

Wicket packs certainly have numerous advantages that make them popular across industries. First of all, it is their universal nature and flexibility of use. From the food industry to pharmaceuticals and household needs, wicket bags can meet the needs of various types of products.

One of the key advantages is their ability to preserve the freshness and quality of products thanks to their tightness and barrier properties against light, oxygen and moisture. This is especially important for perishable or sensitive products.

Further, wicket packs provide convenience in use and transportation. They can be easily opened and closed, making them ideal for consumers. They are usually light and compact, which makes them easy to carry and store.

In addition, wicket packs can be custom designed, allowing companies to create unique packaging that matches their brand and grabs the attention of consumers on store shelves.

Finally, their environmental friendliness should be noted. Some wicket bags can be made from recycled materials or be biodegradable, which helps to reduce the impact on the environment and increase the sustainability of the product.

Wicket package production technologies

Wicket bags are manufactured using special technologies and equipment that allow you to create bags with vacuum or air packaging. These technologies make it possible to manufacture wicket packages in different sizes, shapes and with different functional characteristics for different programs.

Film extrusion

This is one of the main processes involved in making the film used to make wicket packs. In this process, a plastic material (such as polyethylene) is heated and passed through an extruder, where it turns into a film. The film is then cooled and wound on reels.

Film forming and cutting

The film that came out of the extruder can be subjected to further shaping and cutting with the help of special equipment. This process involves forming the packages into appropriate sizes and cutting them into individual or combined packages.

Additional processing

After the film is formed and cut, the bags can be further processed, such as printing, protective coating, or adding special features, such as air bleed valves.

Vacuum packaging

This process includes vacuum packaging of goods in wicket bags. After placing the goods in the bag, it is vacuumed to remove air and create a vacuum environment inside the bag.

Sealing

After vacuum packing, the bags are sealed to prevent air from entering. This process may include heating the edges of the bag or using special adhesives or plastic tapes to create a hermetic seal.

Production of wicket packages in Ukraine

Creation and purpose of the company for the production of packaging products

Wicket packages from the manufacturer in Ukraine Smart Pack LLC is the perfect choice for your business. Our wicket bags are made of high-quality materials and are durable and reliable, ensuring safe and efficient packaging of your goods. They can be made in different sizes and designs to suit your needs and brand.

Our wicket packs allow you to make efficient use of retail space, providing an attractive display of your product on the shelves. Choose wicket packages from "Smart Pak" LLC for reliable and professional packaging of your products!